Characteristic of the PWR

Pressurized Water Reactor (PWR) Features

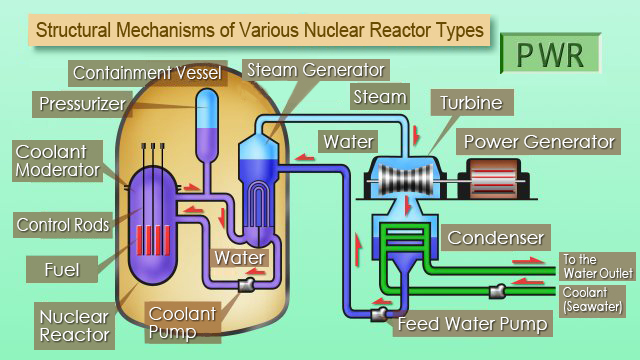

The main feature of pressurized water reactors (PWR) is that the water that comes into direct contact with the fuel rods (primary cooling water) and the water that is boiled into steam to turn the turbines (secondary cooling water) are completely separated.

High pressure is applied to nuclear reactors during operations (approximately 157 atmospheres), and the cooling water inside the reactor reaches a high temperature (approximately 320 degrees Celsius) without boiling. This high-temperature primary cooling water is passed through the steam generator to heat the secondary cooling water, where it cools itself before being returned to the reactor. The secondary cooling water heated in the steam generator turns to steam and is used to turn the turbine generator, which produces electricity.

Steam Generator

The steam generator passes the primary cooling water through many narrow pipes (heat transfer tubes) to ensure that heat is efficiently transferred, thereby heating the secondary cooling water on the outside of the pipes. Since the steam generator’s heat transfer tubes play an extremely important role in separating the primary cooling water from the secondary cooling water, regular inspections are carried out to ensure that no cracks or other problems have occurred.

Reactor Vessel

The reactor vessel is filled with the primary cooling water under high pressure (approximately 157 atmospheres) during operations. Control rods are inserted from the top into the reactor core with pressurized water reactors, and mechanisms for operating the control rods are located on the top cover of the containment vessel.

Containment Vessel

Pressurized water reactors are equipped with large storage containment vessels containing the reactor, steam generator, etc. They are designed to alleviate rising internal pressure caused by a loss of primary coolant.